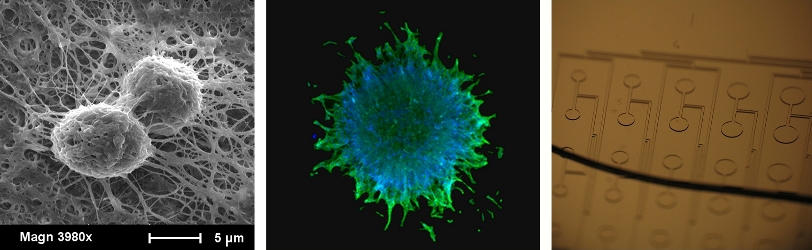

What started out as a disastrous experiment to make hand-pulled cotton candy in Chris’ kitchen turned into a pretty sweet technique to microfabricate structures in really soft silicone materials (published in Lab on a Chip last week). Generating structures in materials that have the consistency of watered-down pudding is particularly challenging, as peeling away a mold tends to destroy the structures. While experimenting with candy-making, instead of creating delectable, delicate and light sugar structures, Chris ended up with a hard lump of sugar that tasted horrible – but seemed to hold the microscale features of his Ziploc plastic container rather well. He raced that lump down to the lab, and after some modifications, found that (a) designer hard candies can hold microscale features, (b) that PDMS can be cast and cured against the candy, and (c) the candy could be gently removed by dissolving away in warm water. We then used microengineered soft molded structures to measure contraction of engineered microtissues, as a simple demonstration of this fabrication technology. Seems quite promising for many applications in soft matter engineering, and as an added bonus, the lab smells *delicious*.

[UPDATE: lots of news coverage on this piece! Check out the publications page for links]